LMF

Low Melting Bonding Fiber

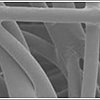

LMF, which is produced by bicomponent spinning of general polyester and modified polyester, can be melted at lower temperature(110~200℃) than normal fiber and bonded with other fibers.

Feature

Excellent Bonding Properties

LMF provides diverse melting points generated through controlling seath part (modified polyester).

Excellent Durability

The bonding strength after being combined with other fibers hold out semipermanently.

Easy Mixing Properties with other Fibers

Homogeneous properties between LMF and various Fibers make blending easy on line.

Excellent Resilience

The formation of non-woven fabric made with LMF is simple and excellent.

Applications

Automotive Use

Car-Interior, Doortrim

Bedding

Mattress, Quilting, Padding

Industrial Use

Engineering Material, Construction Material (Soundproofing, Insulation), Filter

Hygienic Materials

Hygienic Bonding, Clothing

Production item

| Type |

Luster |

De |

Length(mm) |

Melting Point |

Remarks |

| LMF |

SD |

2/4/6/10/15 |

32~102 |

110,130,150, 180,200℃ |

PET/PET |